The following article was copied in its entirety from the National Precast Concrete Association website and can be found by following this link: http://precast.org/precast-possibilities/case-studies/precast-grease-interceptors-resturant-application/

A simple, efficient solution to a growing problem.

The many thousands of restaurants in the United States serve nearly 70 billion meals a year to their patrons. That s a mountain of food, whose preparation releases an ocean of wastewater into the environment. The need for effective pretreatment of that wastewater is crucial. Ineffective grease removal from these waste streams results in the discharge of large quantities of grease into public sanitary sewer systems. Solidified grease can develop into stoppages in the piping networks downstream and create costly and time-consuming problems at municipal wastewater treatment plants. Grease blockages have been known to cause considerable unnecessary health hazards when raw sewage backs up into residences or commercial establishments. By trapping fats, oils and greases (FOG) and solids normally found in food service establishments, a grease interceptor is the last line of defense against potential problems downstream.

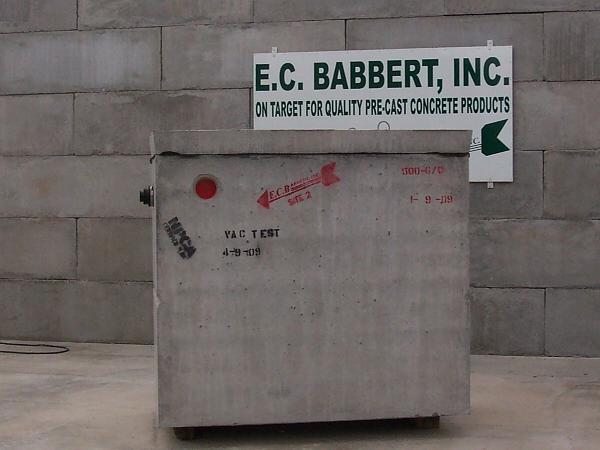

More and more sanitarians and other authorities are realizing that precast concrete grease interceptors are the best solution for FOG removal.

Besides precast concrete grease interceptors, alternative grease separation devices such as small under-the-sink metal grease traps (sometimes referred to as hydromechanical grease interceptors) have been used at many food service establishments. These small grease traps are often woefully inadequate for commercial establishments. Whatever the system in place, in order to allow for adequate separation of the FOG from the waste stream, all grease separation devices must be designed with the following criteria in mind:

Retention time

Greases and oils have a lower specific gravity than water, so when a grease-laden mixture is left undisturbed, they will float to the surface. As such, there must be sufficient time for this process to occur. Smaller devices should be carefully evaluated for retention time. Metcalf & Eddy, an internationally acclaimed company that delivers a full range of environmental services, recommends a minimum retention time of 30 minutes to adequately separate a grease-laden mixture.

Flow

The grease separation device must be sized and configured to allow for sufficient retention time, taking into account the flow rate of the influent. Furthermore, it must be configured to minimize turbulence and allow the suspended FOG to separate. This is especially important in high-flow situations, such as when draining a large sink.

Storage capacity

The device must be large enough to allow for sufficient storage of accumulated FOG between cleaning operations without affecting the flow characteristics through the unit.

Cleaning frequency

The grease separation device must be sized according to realistic cleaning frequencies. Under-the-sink grease traps must be cleaned out routinely, even daily. There is generally no assurance that restaurant personnel will maintain the unit properly, so routine cleaning performed by a third party will more likely result in proper maintenance and supporting documentation.

In addition to all of the previously mentioned design considerations, consider that soaps and other emulsifying agents have a significant impact on the amount of time required for the FOG to adequately separate. Here is a quick and easy demonstration that shows how soap drastically increases the time it takes for FOG to separate effectively:

Take two identical jars with lids, some vegetable oil and liquid dish soap.

Add a few tablespoons of the oil to each jar and fill them with water.

Add a couple of drops of the dish soap to one of the jars, then close both lids tightly.

Shake both jars for about one minute, then set them down and start a timer.

Note the amount of time is takes for the oil to separate in each one. There will be a significant difference between the two.

Given that all restaurants use soap, it should be apparent that soaps effects on separation time should be considered in the design for grease separation devices. There are many variables that affect the separation rate of emulsified FOG. As such, consider that the separation time will be increased by soap in order to ensure an appropriate minimum retention time.

Outdoor precast concrete grease interceptors can definitely accommodate all these design requirements. Retention times in excess of 30 minutes are easily achievable. Baffles and large liquid volumes help reduce turbulence and provide for a high storage capacity. Outdoor interceptors can provide maintenance accountability because of their reliance on third-party maintenance contractors. Another consideration is that outdoor interceptors provide a level of health and safety that indoor traps cannot provide. By physically removing the collection, maintenance and disposal of grease outside the kitchen area, outdoor interceptors eliminate the health concerns otherwise created by providing these functions in the same workspace as food preparation.